MECHANICAL MANUFACTURING FACILITY

Department of Production Engineering has the facility to design, develop, and manufacturing systems with the following laboratories.

1.Adanced CAD lab

2. Metal Forming lab

3. Advanced Maching lab

4. Robotics and Automation Lab

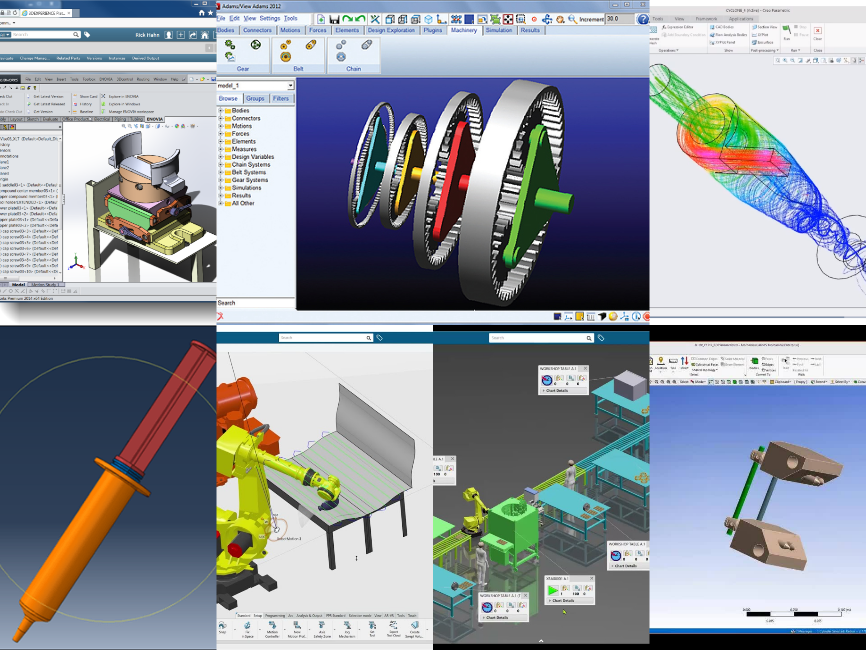

- The design, simulate and analyse pattern provides high flexibility and efficiency. All the individual components are designed accurately and analysed to their strengths and weakness. This greatly decreases the time during the fabrication and assembly stage. The failure analysis of each and every component at different stages of manufacturing improves the quality of the product.

- All the components for the products can be modelled and designed before manufacturing. The CREO and CATIA software are used to model and analyse the position of different components in the products. This makes the assembly process easier.

- All the designed components must be analysed for stress for its longevity. The ANSYS & ABAQUS software is used for the various analysis and simulation in structure, heat transfer for designs of the products.

- All the kinematics, dynamics and physics involved in the mechanism can be analysed and evaluated using ADAMS. The entire product lifecycle and production at different stages are monitored using DELMIA Virtual Manufacturing Software.

- Sheet metal enclosures and covering sheets of products are fabricated to the highest accuracy using a CNC Power Press brake. The machine consists of a double ram configuration of 15 Tons capacity each is capable of handling sheets up to 4mm thickness and maximum component width ranging from 50-1000mm. Manual Bending Machine is used for small components which require less tonnage for bending.

- Stamped components and perforated sheets can be fabricated using the CNC-controlled hydraulic press. It is capable of generating 40 tons of force for punching, coining, and forging operations. It is also capable of making compression molding components.

- Fasteners and threaded parts can also be machined in-house at MIT. The Thread rolling machine (Hydraulic) is used for this above requirement which is capable of making standard metric threaded parts from M2 to M12.

- Manufacture and production of polymeric components at high volume can be done using the Injection Moulding Machine.

- The components needed for the fabrication of the Gantry, screws, nuts, XY-table arrangements etc. can be machined to a desired shape and size with the help of a 5-axes CNC Machining Centre. Haas 5-axes CNC Machine is a highly advanced specialized machining Centre to machine intricate components needed for product development. The special feature of the machine is that the complex contouring can be done with the use of 4th axes (rotation of head) and 5th axes (swivelling along the z-axis).

- The turning requirements of hardened metal components like ball screws, and ball nuts can be machined to the desired size with the help of the CNC Turning Centre. CNC Turning Centre is ideal for short-run volumes and especially for building prototypes and parts for products.

- Automatic loading of raw materials into the machine and unloading of the finished component from the machine is highly important for technology transfer to industry for regular production and avoid human fatigue. To achieve this objective, a 3-axis Gantry Robot is installed. The three-axis gantry robot consists of a manipulator mounted on an overhead system that allows movement across a horizontal plane. The 3-axis Gantry Robot is capable of continuous transfer of components between the CNC Turning Centre and 5-Axes Machining Centre for continuous operations on parts loading and unloading

- Several complex and critical components can be positioned and welded accurately. The ABB 6 Axis Robot is an Industrial Robotic Arm is an industrial robotic manipulator that can weld components accurately with great repeatability.

- The 6 Axis Lightweight Torque compliant Kinova Robotic Arm is a highly advanced robotic arm made of Carbon fibre. It can be used for research and analysis of robot kinematics and dynamics. The Robots can handle several complex tasks, and the related solutions need efficient algorithms. The TAL 5-Axes robot is used for the research, design, and development of such algorithms. The Robot can also be used for pick & place applications. The haptic device provides force feedback and allows to enhance scientific or medical simulations.